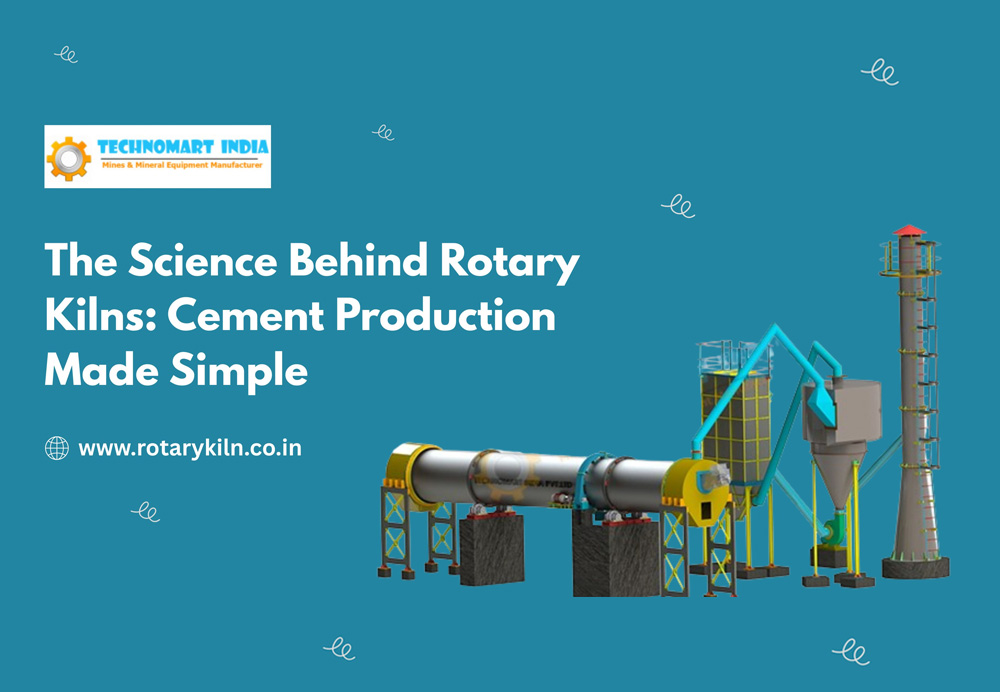

Rotary Kiln Manufacturer

Where innovation meets combustion, Technomart India fuels your production with advanced rotary kiln solutions Based in Gujarat we are the biggest Rotary kiln manufacturer in India.

Technomart Engineers Pvt Ltd. mastery in constructing well-engineered kilns with more than 25 years of experience has placed us among the most trusted Rotary kiln manufacturer. Presenting our state-of-the-art rotary kilns crafted for unmatched efficiency, durability, and precision.