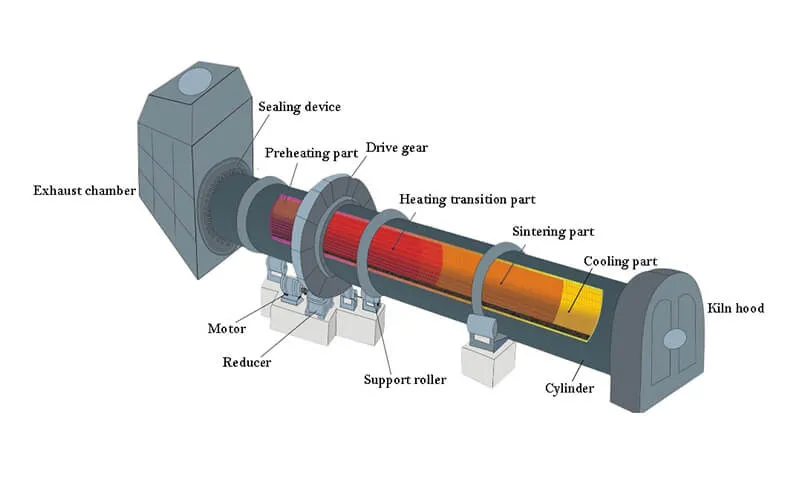

A cement rotary kiln is a big, circling kiln operated to process materials like limestone and clay for producing cement. It blends the compound at extreme temperatures, forcing the materials to experience a chain of chemical shifts that transform them into clinker, which is a major element for cement production. The kiln spins gradually along with a slightly inclined position, permitting the materials to move through varied stages of heating and cooling, which is a important for reaching the expected quality for the outcome. This equipment fulfills a significant role in the cement production process and has been improved over some time to minimize energy utilization and reduce environmental footprint.