Investing in a rotary calcination plant is not just about upgrading equipment—it’s about transforming productivity, optimizing energy usage, and reducing overall operational costs.....

Rotary kilns have long been the central equipment in cement manufacturing. Their function is simple: heat raw materials to form clinker. However, the technology around them has advanced rapidly.....

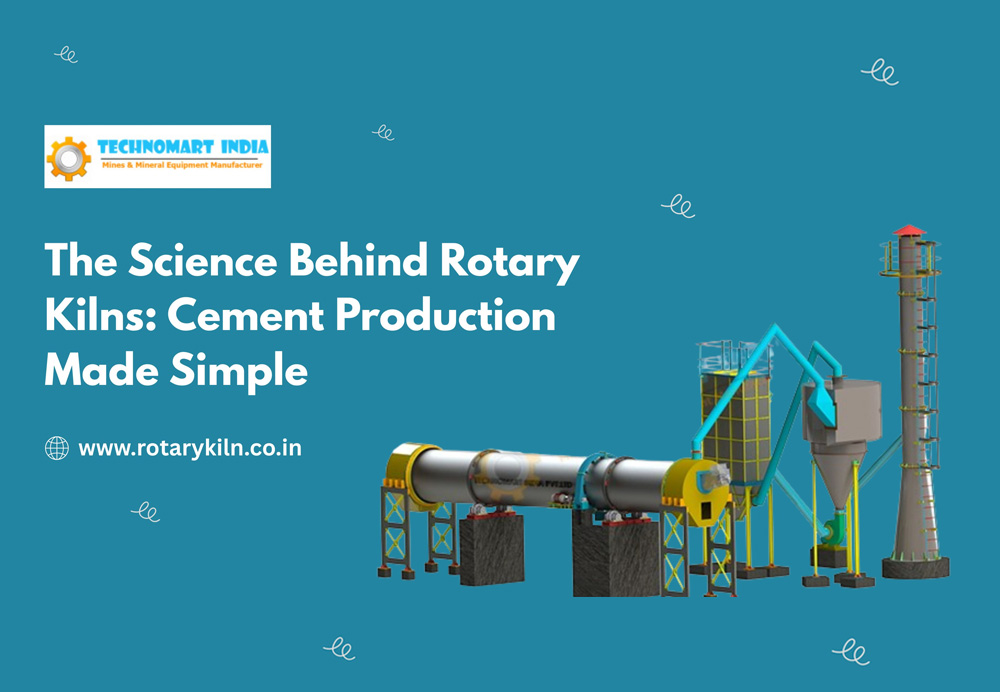

Rotary kilns are central to cement production. These large, rotating cylindrical furnaces convert raw materials into clinker. The process is continuous, efficient, and precise. Understanding rotary kilns simplifies cement manufacturing.....

A rotary kiln is a cylindrical furnace used for high-temperature processes. It rotates slowly, allowing raw materials or waste to be heated evenly. These kilns have a strong role in waste treatment, metallurgy, and cement manufacturing......

Cement is the foundation of infrastructure in both urban and rural areas. While large rotary kilns dominate big cement plants, vertical shaft kiln (VSK) plants remain vital for rural regions. They provide affordable, localized cement production, ensuring that villages and small towns can access the material needed for housing, schools, and roads.....

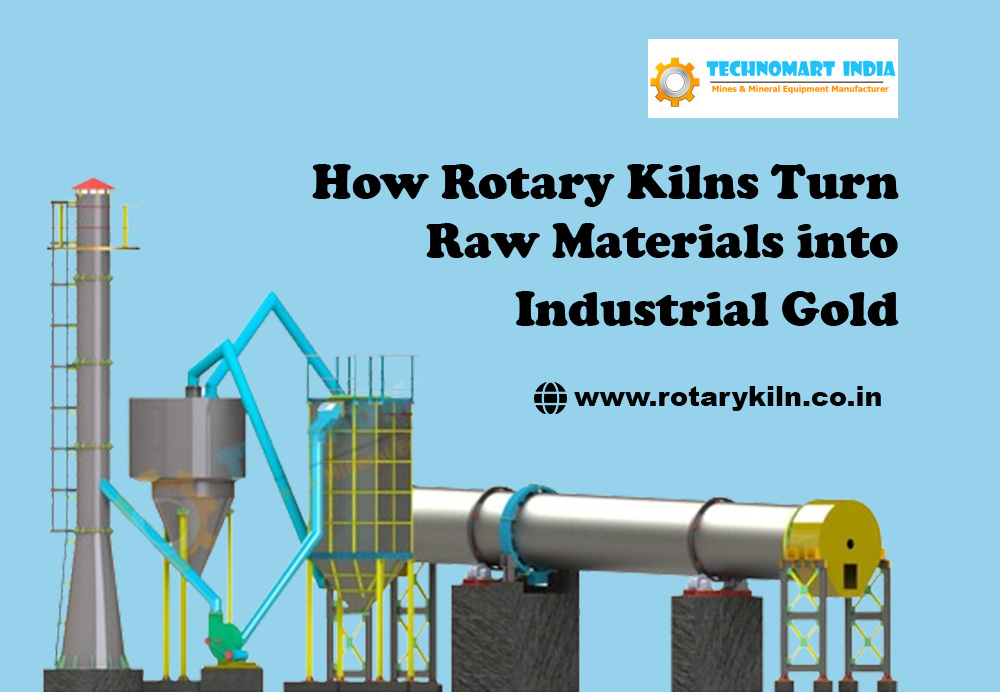

Rotary kilns are rotating furnaces designed to process raw materials under controlled heat. Their ability to induce chemical and physical changes makes them indispensable in modern industry. .....

Rotary kilns play a pivotal role in modern industry. They are used in cement, lime, refractories, chemicals, and metallurgy. Their ability to process raw materials into usable products makes them vital for industrial development......

A rotary kiln is a long, cylindrical furnace used to process raw materials at high temperatures. It rotates slowly on its axis, ensuring even heating and material mixing. This equipment is essential in industries like cement, lime, metallurgy, and waste treatment.....

The rotary kiln has evolved significantly since its inception. In this blog, we will explore the evolution of rotary kilns, their essential factors and impact on modern cement manufacturing. Before understanding the importance and evolution of rotary kiln let’s know “What is rotary kiln”....