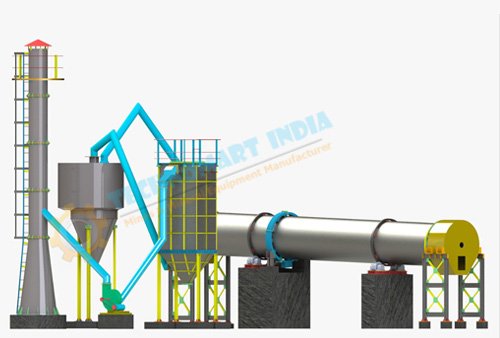

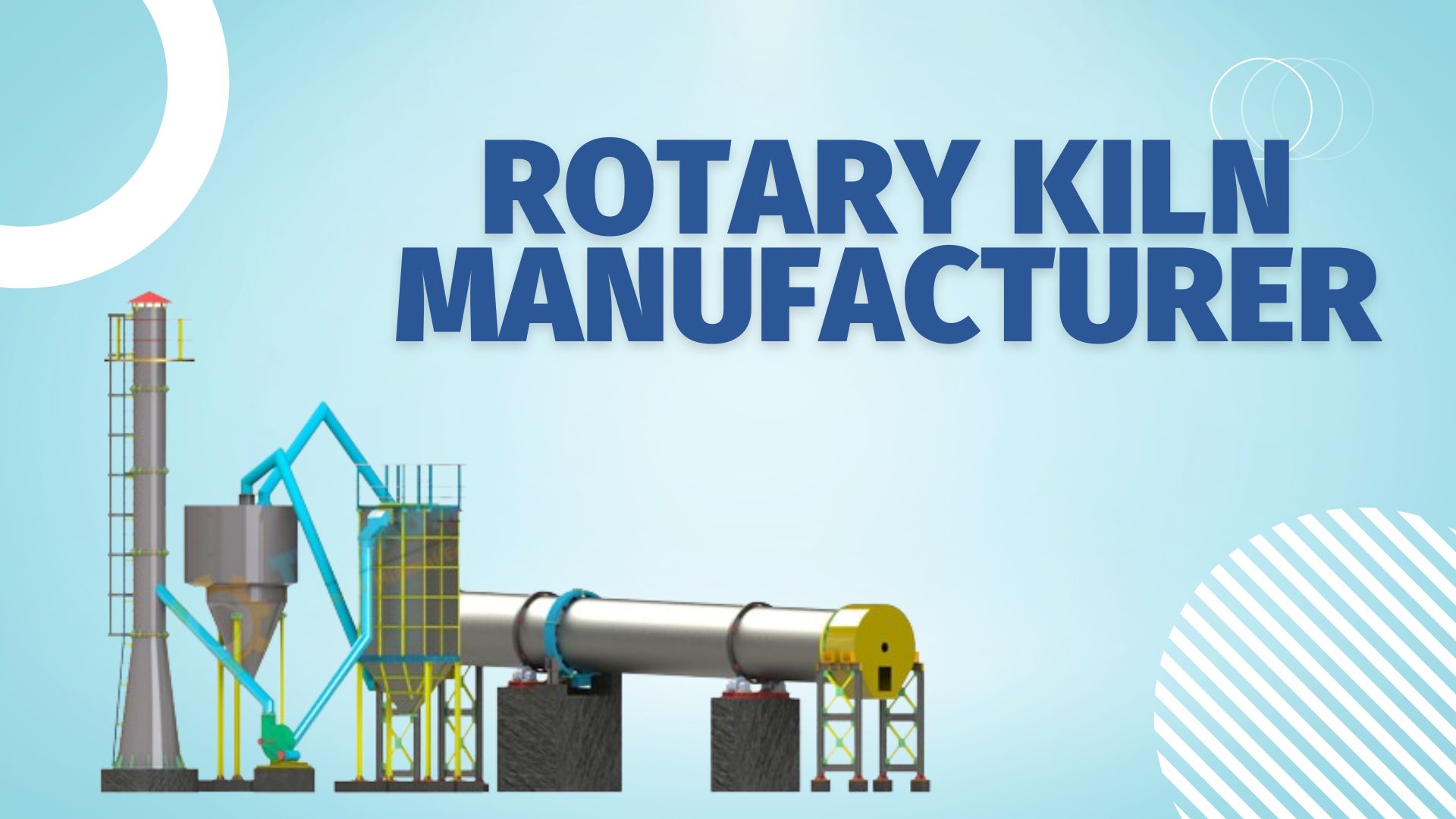

Rotary Kiln Manufacturers in Ghaziabad

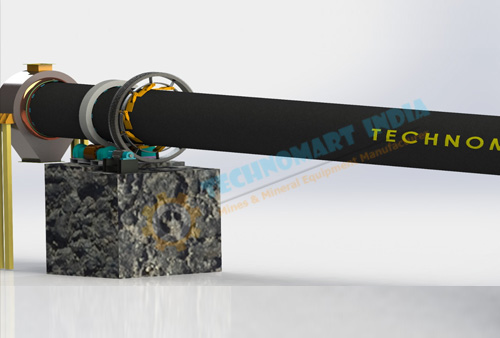

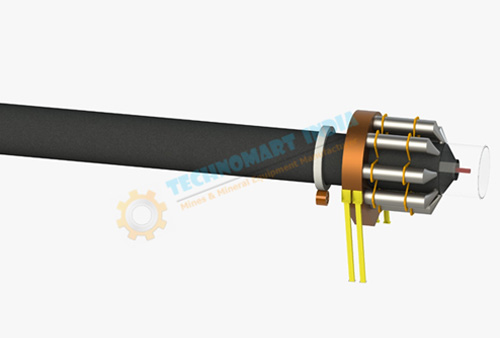

Rotary kiln is a cylindrical and long rotating furnace that is used in various industries in order to heat, process, and treat raw materials at a high temperature. It is an continuous process with an aim of moving the materials bit by bit on one end to the other end so that it can be exposed to controlled heat. With a slow rotation of the kiln, the material falls and blends together, so that all the material is exposed to the heat and this results in chemical or physical modifications like calcification, drying, sintering or pyrolysis.

Rotary Kiln Manufacturers in Ghaziabad have been known to provide robust, energy-efficient and high performance kilns that are used in cement, lime, metallurgy, chemical and waste-processing plants. With advanced production facilities, quality engineering practices, and a strong focus on innovation, Ghaziabad-based companies have become leading rotary kiln suppliers not only in India but also in global markets.